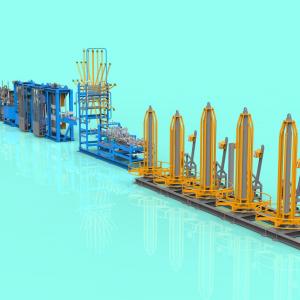

Description

The intelligent automatic steel bar cutting line adopts a servo motor, which has high cutting precision. The sawed steel bar is automatically divided into materials and convenient for threading; the distance between the cutting blade and the positioning baffle is adjusted by the frequency conversion motor driving the screw mechanism. It adopts encoder to measure, the accuracy of sizing is high, up to ±2mm, and it can cut steel bars of various lengths. Each part of the intelligent automatic steel bar cutting line adopts an adjustable foot plate design, which can be adapted to different heights of ground and adjusted separately.

1. The small angle design of hydraulic scissors reduces the lateral force that the frame bears during shearing and improves the service life; the scissors fixing frame is rigid enough and has good integrity; the guide adopts flexible materials and has an adjustment structure, which can be effective Prevent the impact on the scissors holder when there are obstruction points.

2. There is a scissor roller table before the hydraulic shears, and the end close to the scissors is equipped with two air cylinders to control the lifting of the roller table. When the steel bar is cut, it can move synchronously with the hydraulic cylinder to ensure that the steel bar feeding end is in the cutting Will not deform.

3. The roller table after cutting is driven by a screw lifting motor as a whole, which can adjust the size quickly and conveniently.

4. The discharging rod of the roller conveyor after shearing is divided into three sections, which can meet the needs of independent work, coordinated work, and simultaneous work according to different steel bar lengths, which can save air consumption and improve response speed.