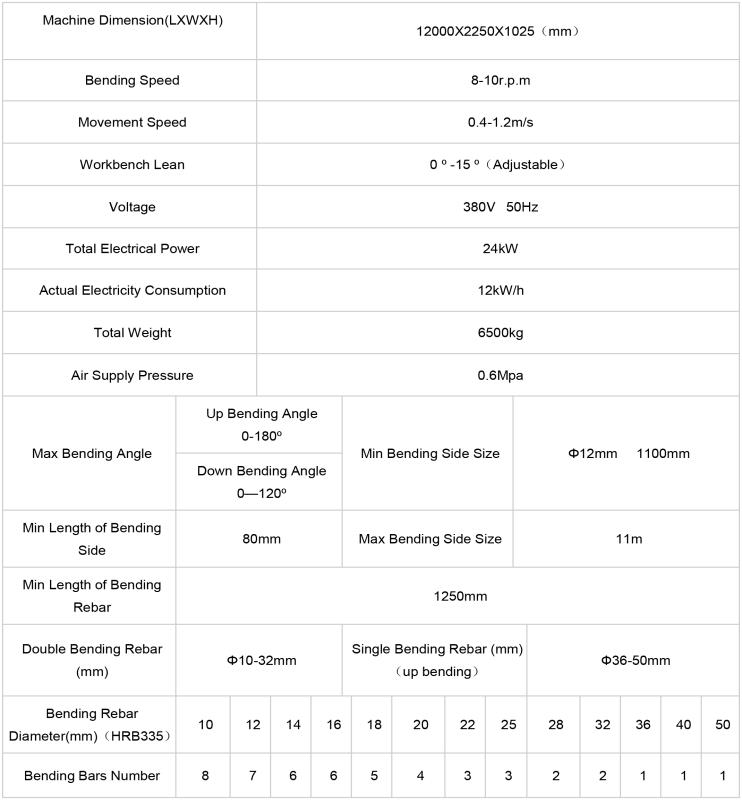

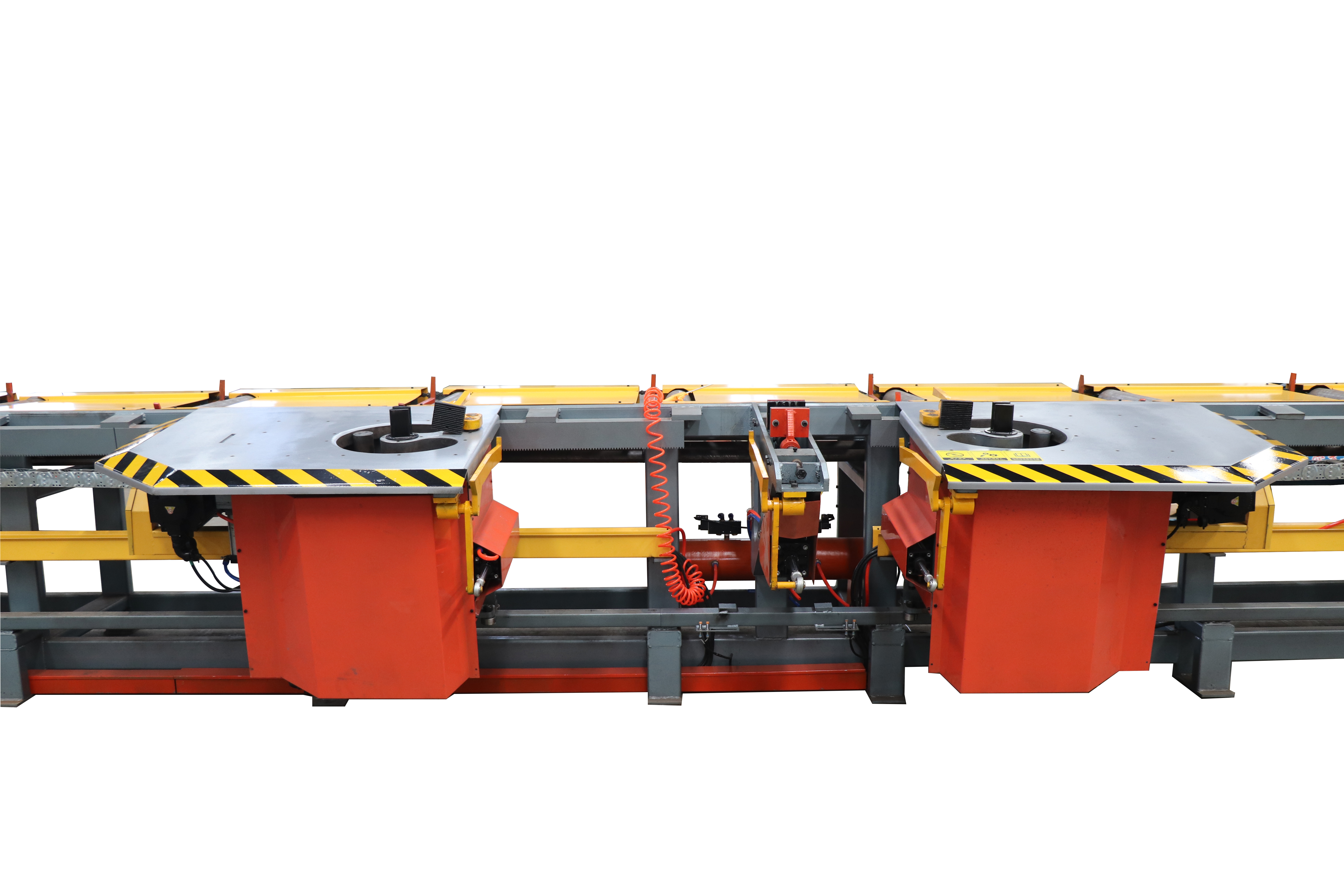

horrizontal rebar bending machine luyuan made

Performance advantages: 1. The CNC steel bending machine adopts automatic, servo motor drive and rack and pinion transmission, so the design difference is relatively small, but the reverse is also fast. 2. The CNC steel bar bending center is an integrated design with a high-speed rail design. The operation is relatively simple, and the feeding rack can be bent at multiple angles in one cycle. 3. The bending accuracy of the CNC steel bar bending center is relatively high. It can be driven by a servo motor, and the fixed-length accuracy is also high. It can realize the functions of automatic fault identification and graphic editing.

Therefore, when doing industrial design, it is necessary to combine the background of the new era, actively refer to advanced design concepts and science and technology, and continuously improve and innovate on the basis of which can design more and higher-quality products, and then demand for industrial products in the current era. , Not only is conducive to the further development of industrial modernization, but also fundamentally industrial design and efficiency. Structural innovation Structural innovation is not to create new things, but to continuously improve and innovate the organization. Through the relationship between elements, it promotes its internal structure to be more reasonable and scientific, and thus can achieve a more coordinated overall effect.

The emergency stop switch on the steel bar bending center console should be in an easy-to-control state, and the surrounding space should be large enough to facilitate the emergency stop of the staff and avoid it. CNC steel bar bending machines are mainly used for highways, high-speed railways, hydropower projects, and large bridges. The main skeleton steel bar in the concrete structure of other projects is bent, and the steel bar bending range is 10mm-32mm. If there is a problem with the operation, please call directly. There is a tightening mechanism in the middle of the steel bending center. The two heads are on a specific track. If heavy load operation will increase the wear, how can the CNC steel bending center wear? When using the steel bending center , I suggest you don't overload your work.

The emergency stop switch on the steel bar bending center console should be in an easy-to-control state, and the surrounding space should be large enough to facilitate the emergency stop of the staff and avoid it. CNC steel bar bending machines are mainly used for highways, high-speed railways, hydropower projects, and large bridges. The main skeleton steel bar in the concrete structure of other projects is bent, and the steel bar bending range is 10mm-32mm. If there is a problem with the operation, please call directly. There is a tightening mechanism in the middle of the steel bending center. The two heads are on a specific track. If heavy load operation will increase the wear, how can the CNC steel bending center wear? When using the steel bending center , I suggest you don't overload your work.

As information technology is widely used in manufacturing, industrial design concepts and technologies are also changing rapidly. With the goal of enhancing students' practical ability in the new industry, a modular industrial design interdisciplinary practice platform construction and application plan is proposed. A complete manufacturing is established on the hardware, and the real product design process is condensed and reproduced in the platform, and students' knowledge use and collaborative innovation ability are enhanced. Shanghai promotes the construction of professional curriculum system and teaching staff through platform construction, and plays an important role in the use of talents. Key words: industrial design; interdisciplinary; practical studies. Entering the century, "re-industrialization" has been developed and developed.

Virtual reality technology is not affected by region and space, product design modification is faster and more convenient, so that design process and time can be researched and developed efficiently, the product development cycle is greatly shortened, and the labor intensity of designers is greatly reduced. ) In industrial design, some industrial products may be dangerous or very expensive to build. In this case, using virtual reality technology will effectively solve these problems. For example, after the transportation design is completed, most of the customers need to visit other cities where the installation has been completed. With the help of virtual reality technology, the simulation of local roads or urban traffic conditions can be achieved, and product design will be more targeted.

The bending center is an economical automatic bending equipment for steel bars, which mainly bends fixed-length steel bars into different shapes. This machine can bend steel bars in both directions at the same time, with a high degree of automation and convenient operation; this machine is equipped with an automatic device, which can complete the bending work phase of two bending machines. The performance characteristics of the steel bar bending center: 1. The equipment has two positive and negative bending stirrups, which greatly improves production efficiency, shortens operation time and labor costs. 2. Well-known brand servo control, reasonable bending host structure design, large bending force, convenient and accurate angle adjustment. 3. Automatic, using servo motor drive and sprocket chain drive, with small error and fast reverse. 4. The electric control adopts PLC programmable control, which can realize the functions of automatic fault identification and graphic editing. 5. Multiple steel bars are formed, and the production efficiency is high. It is a tool for realizing the construction of steel bar processing plants. 6. The bending head has a compact structure and a wide range of processing steel bars.