Description

Key Advantages of LYGH-2600mm Rebar Cage Rolling Welding Machine

1. High Precision & Consistency

Ensures extremely precise spacing of longitudinal and spiral rebars, guaranteeing consistent quality and structural integrity for every cage, which is crucial for large-scale projects like bridges, piles, and foundations.

2. Exceptional Production Efficiency

Dramatically increases output compared to manual fabrication. Capable of producing large-diameter, long-length cages continuously, minimizing downtime and maximizing throughput for demanding construction schedules.

3. Superior Automation & Labor Savings

Highly automated process significantly reduces reliance on skilled manual labor. Minimizes human error, lowers labor costs, and improves overall workshop safety by reducing workers' exposure to heavy lifting and welding hazards.

4. Remarkable Flexibility

Easily adjustable for different cage diameters (typically up to 2600mm or as specified), lengths, and rebar specifications. Quick changeover between designs enhances its suitability for diverse project requirements.

5. Enhanced Structural Integrity

Produces cages with uniform welding quality and optimal alignment. This results in stronger, more reliable reinforced concrete elements that precisely meet engineering design specifications.

6. Reduced Material Waste

Precise cutting and bending mechanisms optimize rebar usage, minimizing scrap material and contributing to significant cost savings and more sustainable operations.

7. Improved Working Environment

Automates the most strenuous and potentially hazardous tasks involved in cage fabrication, leading to a safer, more ergonomic, and controlled production floor.

8. Long-Term Cost-Effectiveness

While requiring a higher initial investment, the machine offers an excellent return on investment (ROI) through sustained high productivity, reduced labor costs, minimal rebar waste, and consistent output of superior-quality cages.

In summary, the 2600 Rebar Cage Rolling Welding Machine is a cornerstone of modern, industrialized construction. It delivers unmatched precision, efficiency, and reliability in prefabricated cage production, making it an indispensable asset for large-scale infrastructure and building projects worldwide.

Reinventing Construction Efficiency

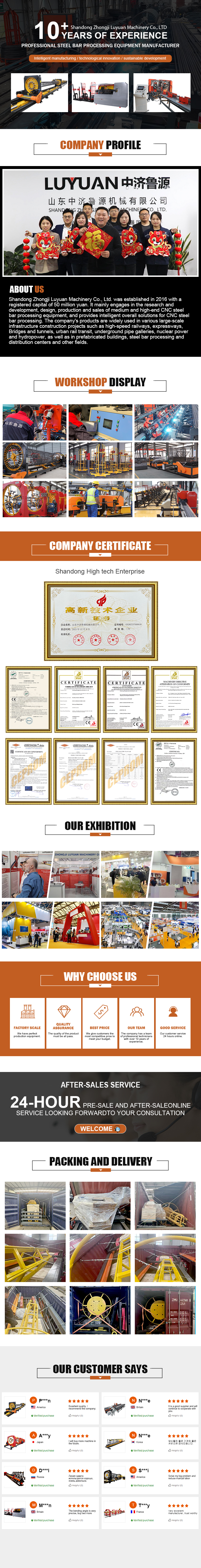

Our expertise lies in designing, manufacturing, and delivering state-of-the-art machinery for fully automated production of prefabricated reinforcement. We are committed to propelling your operations into the future with our cutting-edge technology.

Unleash the power of efficiency and precision with our cutting-edge Pile Cage Machine! Engineered to create cylindrical and rectangular cages when required, this modern machinery produces top-tier structural steel reinforcement cages tailored for columns and both bored and driven piles.

Take a leap into the future with our automatic welding robot. This high-tech wizard guarantees impeccable connections between the spiral wire and longitudinal bars. Whether you prefer manual or automatic feeding from the rebar, this machine has you covered. The coil executes the spiral wire journey through a wire guide strand and guide rollers all the way to the welding roll. Experience the convenience of our hydraulic cage supports that automatically activate during production, lending stability to the entire process.

We’ve incorporated a MIG/MAG welding machine that delivers unparalleled welding quality, especially notable when dealing with rebars of larger diameters.

Experience a new standard of operation with our advanced touchscreen interface. Easy programming and data settings of the reinforcement cage and welding parameters are all a touch away. It couldn’t be easier or more efficient, with pre-stored programs ensuring seamless workflow.