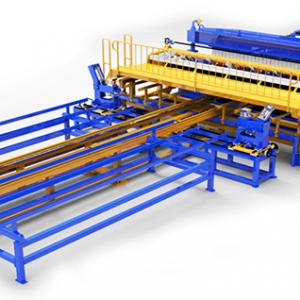

luyuanmachinery launched new cage welding working station

|

Serial number |

denomination |

parameter |

|

1 |

Device Model |

LYQZD-GJL02 |

|

2 |

Device Name |

Fully automatic rebar cage welding station |

|

3 |

Rebar cage diameter |

φ 1200mm-φ2500mm |

|

4 |

Diameter of main reinforcement cage |

φ 18mm-φ32mm |

|

5 |

Rebar cage diameter |

φ8mm, φ 10mm, φ 12mm, φ 14mm, |

|

6 |

Main reinforcement type of steel cage |

Single main reinforcement, (double main reinforcement-customizable) |

|

7 |

Steel Cage Wire Wrap Type |

Single winding and double winding |

|

8 |

Rebar cage spacing |

70mm-300mm |

Product Description

The fully automatic steel cage welding workstation is a steel cage

welding equipment with independent intellectual property rights

developed by our company. The equipment is mainly used in subways, bridges, building construction, airports, highways, and foundations.

This equipment consists of a main reinforcement automatic feeding

system, a main reinforcement detection and positioning welding

system, a steel cage welding system, and a steel cage unloading system. No human intervention is required during the welding process. The

welding efficiency is high. The welding time of a main reinforcement is less than 35 seconds. The welding time of the welding point can be

configured and saved according to the process, which saves personnel and greatly improves the welding efficiency. It can ensure continuous and rapid welding. The steel cage skeleton of 9 meters to 12 meters can generally be welded in 20 minutes, and the steel cage can generally be wound and welded in 25 minutes. The welding quality is good, there is no false welding, the quality is reliable, and the welding time and

welding position are accurately controlled to save welding materials.

The system supports the preset of multiple sets of steel cage

specification parameters. Workers can directly call data and use one-key operation on the touch screen during processing. The assembly line working method is simple and intuitive, with a high degree of automation. The product quality fully meets the specification requirements. When the steel cages are actually produced manually,

the project supervisor visits the processing site for inspection almost every day. However, after using the fully automatic welding

workstation for steel cages, all information equipment can

automatically monitor and record the welding process in real time, and report various monitoring information in a timely manner to ensure

stable and reliable processing quality. Product Features

This fully automatic steel cage welding workstation developed by our

company fully considers the safety, comfort, simplicity and

convenience of users. Taking into full consideration the operating

habits of workers on the construction site and the need to quickly get started with new products, the equipment operation has been specially optimized. After the equipment is debugged, all parameters that need to be input for later product type changes are intuitive and measurable (parameters that need to be set after product adjustment: steel cage diameter, winding diameter, number of main bars, welding time, etc. are all input in a wizard-style manner, and the input data is checked for rationality, which greatly improves the accuracy and convenience of the input data). At the same time, the system separates information

input, parameter setting permissions and equipment operation

permissions, and isolates system parameter settings, workpiece

processing specification information input, and worker processing

operations on the operation interface, which not only avoids the wrong modification of parameters, but also ensures the clarity and simplicity of the worker operation interface. During the period when the product specifications remain unchanged, the equipment can realize one-key

automatic operation, and the equipment will automatically perform all welding and testing work, and automatically stop and broadcast a

message to remind the workers when the welding is completed. The equipment is designed to work 24/7, which greatly improves

production efficiency and becomes a strong supporter of the project progress. During the normal welding process, no personnel need to

stay, so that the operator can carry out other preparation tasks.Reduce the labor intensity of workers. The extremely intelligent design of the product can greatly reduce the misoperation of personnel, and it takes only a few minutes to become familiar with the operation of the

equipment. Shandong Zhongji Luyuan Machinery Co., Ltd. insists on using technology to reshape the research and development concept of an industry. On the premise of ensuring the construction quality, it

simplifies the operation steps of personnel by improving the

intelligence of the product, and reduces the skill requirements of personnel to achieve the purpose of quality assurance, efficiency improvement and cost reduction for cooperative enterprises.

In particular, the product has the following characteristics:

1. Fast speed: The welding cycle time of each main reinforcement is less than 35 seconds.

2. Stable quality: Mechanized operation is not affected by human factors, and the quality can be stabilized for a long time.

3. It is suitable for the design requirements of the number, form, model, size and length of various main reinforcement stirrups, and will not

affect the design of the steel cage and the scattered mobile operations on the construction site due to the function of the equipment.

4. Convenient operation: The combined design makes the handling,

installation, production and other processes convenient, and adapts to the factory-based large-scale fixed production and the scattered mobile operations on the construction site.

5. Realize fully automatic welding of steel cages, improve work

efficiency, reduce manual work intensity, and improve the welding quality of steel cages.

Equipment use environment and conditions

|

No. |

Name |

Parameter Attribute |

|

1 |

Power supply |

380V±10%, 50Hz±1, 3-phase 5-wire system |

|

2 |

Ambient temperature |

-10-60°C

|

|

3 |

Humidity |

≤85%

|

|

4 |

Continuous working time |

≤24h

|

|

5 |

Power Equipment power: |

30KW; welding power: 100KW

|

|

6 |

Compressed gas pressure |

≥0.6MPa

|

|

7 |

Shielding gas Mixed gas |

(80%Ar+20%CO2)

|

|

8 |

Welding wire |

1.2mm welding wire |