Description

The main technical parameters:

1. Maximum sawing specifications: Effective cutting height: 700mm

Throat depth: 950mm

Effective cutting stroke: 1000mm

2. Band saw blade specifications: 54×1.6 mm

3. Band saw blade speed: 20-80 (frequency conversion speed regulation)

4. Cutting feed speed: hydraulic stepless speed regulation

5. Machine tool input power voltage: AC 380V, 50Hz

6. Main motor power: 7.5kW

7. Hydraulic motor power: 0.75kW

8. Cooling pump power: 120 W

9. Hydraulic tank volume: 120L

10. Cooling box volume: 150L

11. Workbench bearing capacity: ≥10T

12. Equipment weight: about 5 tons

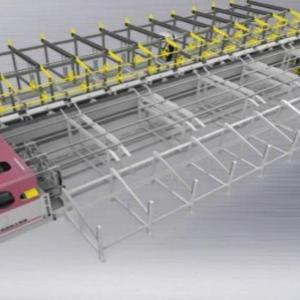

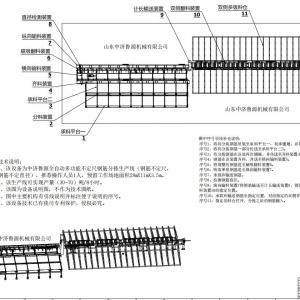

13. Dimensions: See the schematic diagram

Performance characteristics:

1. The saw blade linear speed is 20-80m/min. It is controlled by a frequency converter. It is easy to adjust and has no impact when starting. It extends the service life of the saw blade, reducer, saw wheel and other transmission components; the cutting feed is driven by a hydraulic cylinder and a stepless speed control valve Step speed, stable structure and convenient operation.

2. The movable guide rail of the worktable adopts 5 55# linear guide rails, which has high guiding precision and flexible operation.

3. Steel brush cleaning chip to ensure complete cleaning of sawdust.

4. The main drive adopts a turbo reducer, which has strong power and reliable performance. After precise balance correction, the operation is stable and reliable.

5. Narrow sawing, saving materials, energy saving, high cutting precision, convenient operation and high production efficiency.

6. Reasonable saw band guide device can effectively extend the life of saw band. The transmission parts are balanced and corrected to reduce vibration, and the cutting speed is stable. This precision system can prevent abnormal damage of the saw blade and achieve the ideal sawing effect.

7. Adopting high-efficiency and energy-saving design and concise circuit, excellent space of the electrical box, not only ensure the low failure rate of the machine, but also facilitate maintenance and save time; it also has circulating cooling and overload protection.

8. In order to ensure the reliability of machine operation, the saw blades, guide rails, electrical components and hydraulic components on this machine are all high-quality products of well-known domestic and foreign brands.