The main principle and characteristics of the automatic CNC steel bending machine

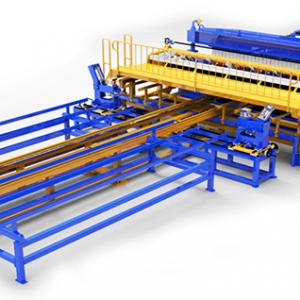

1. Machine structureThe machine structure is mainly composed of: machine base pre-adjustment, traction mechanism, straightening frame, hydraulic cutting mechanism, automatic meter counting device, bending device, bearing frame, walking device, PLC electrical control and other parts.

2. The pre-adjustment part, this part is mainly adjusted by the pre-adjustment wheel so that the wire can better enter the straightening cylinder.

3. The part of adjusting the cabinet. This part mainly adjusts the straightening wheel to make the curve stick reach a certain amount of eccentricity, and the wire rod completes the straightening work in the high-speed rotating straightening cylinder.

Fourth, the traction part, this part is powered by the motor, and the wire is pulled forward by the traction wheel through the reducer mechanism to complete the in and out of the wire.

5. Meter counting device: The electronically controlled length metering device sets the required length on the length of the digitally controlled length metering electronic control screen through the meter sensor (based on millimeters). Then press the OK button to complete the length counting work. The meter wheel rotates with the movement of the wire under the action of the advancement of the wire, and then completes the length counting work through the sensor. When the set length is reached, the sensor transmits the electric signal to the hydraulic part to implement shearing. Wait for the next working cycle after reset. The meter counting device sets the number of roots on the number of CNC electric screens, and then presses the OK key to complete the counting work.

Sixth, the hydraulic cut-off part, this part is powered by the motor to drive the hydraulic pump station through electromagnetic control. Move the piston rod of the cylinder to cut the wire. The movable oil cylinder returns to reset under the action of the spring, waiting for the next work.

Seven, the bending part: This part is bent by the oil cylinder to rotate the eccentric disc to meet the angle bending requirements, and wait for the next working cycle after resetting.

8. The supporting frame part: By cutting the hook, the wire advances along the supporting frame, and after reaching the specified length, the wire is cut off by power, and the wire automatically slides down. Wait for the next working cycle.

Reinforcement hoop bending machine-ten characteristic parameters of hoop bending machine

1. High degree of automation, fast traction speed, high work efficiency and good straightening effect. Automatic straightening and feeding, automatic cutting, automatic hooking.

2. The uniquely designed horizontal straightening mechanism can straighten each steel bar separately, which not only improves the straightening effect in the horizontal direction, but also ensures that the two steel bars are parallel, thus ensuring the quality of the steel bars.

3. The processing size is accurate, and the ∅4-∅12mm hot-rolled ribbed steel bar, round steel, and cold-pressed belt assisted steel bar can be straightened, cut, and bent.

4. The speed of double elbow bending hook at the same time is faster and the efficiency is higher.

5. Using touch screen PLC programmable controller programming, as long as the product size is input, it can be produced.

6. Simple design, simple operation, full Chinese menu display, people who know the straightening machine will learn and learn, and the operation will be taught in three minutes.

7. All rollers are made of high-quality alloy steel, with high hardness, good wear resistance and improved service life;

8. This machine adds an auxiliary straightening wheel at the entrance to protect the driving wheel and the life of the straightening cylinder;

9. Increasing the driving power of the pressing wheel front and rear, making the alloy material more powerful, warranty for one year;

10. Widely used in construction sites and steel bar processing plants