12mm14mm16mm20mm stirrup bender introduction of structure and adevantages

Our products, durable and continuous processing!

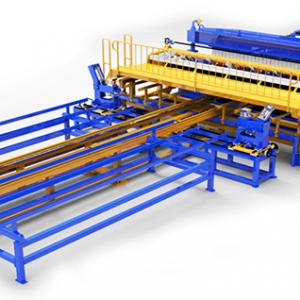

Hello everyone, I am Xiang Jinwei, Technical Director of Shandong Zhongji Luyuan. Behind me is the WG14 steel bar hoop bending machine launched by our company, which adopts the latest technology in Europe and Italy, and eliminates our previous linear and old curved hoop bending machines.Here, I will introduce this product to you by comparing the straight line and the old curved hoop bending machine.

Problem 1 of the linear hoop bending machine and the old curved hoop bending machine: it is difficult to wear bars, and it is even more difficult to wear double bars. And this product of ours is equipped with an automatic feeding motor at the entrance of the steel bar, and matches the latest remote sensing technology, so that one person can easily wear the steel bar.

Use the remote control to operate the prepared double tendons into the traction wheel of the equipment.

The second problem of the linear hoop bending machine and the old curved hoop bending machine: twisted bars and damaged ribs. And this product of ours uses Italian technology - curve straightening traction. It avoids the twisting and rib damage caused by the point contact pressure of the traditional equipment to transport the steel bar, and the steel bar is transported through the line contact pressure to ensure that the steel bar is not twisted or damaged.

Perfectly shaped stirrups.

The third problem of the linear hoop bending machine and the old curved hoop bending machine: the double-line processing and debugging are difficult, and the length deviation is large. And this product of ours adopts the method of pressing double bars by double wheel group and pressing each steel bar independently, which avoids the uneven pressure caused by pressing double bars by a single wheel group, ensures easy debugging of double line processing, and ensures that the size of double line processing is consistent. .

The double-wheel group presses the double steel bars for traction and feeding. The fourth problem of the linear hoop bending machine and the old curved hoop bending machine: the stability of the length and angle of the steel bar is poor. And this product of ours adopts precision planetary reducer transmission in the rapid traction of steel bars and the rapid bending of steel bars, which avoids the force expansion deviation of the synchronous belt drive, ensures the stability of the length and angle of the steel bars, and greatly improves the use of the equipment. life.

Traction and curved planetary reducers

The fifth problem of the linear hoop bending machine and the old curved hoop bending machine: it cannot adapt to the harsh working conditions that are continuous for a long time. The main traction power of our product is a 22KW servo motor, which ensures that "the horse can easily pull the cart for a long time", and avoids the phenomenon of motor heating, alarm and strike caused by the low-power motor "small horse-drawn cart".

device usage video

Our products, durable and continuous processing, work with customers to win the future! Zhongji Luyuan, reduce every drop of sweat!