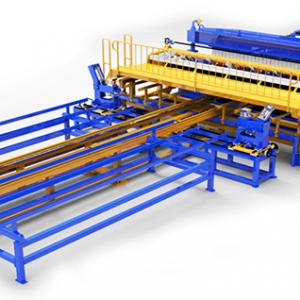

wire mesh welding machine launched new model

The main frame is welded with thick steel plate and section steel, making the main structure more firm and compact. The weft wire blanking mechanism has a novel structure, and adopts a stepping motor to automatically blanking, so that the weft wire can be placed more accurately. Servo motor dragnet device is adopted to make the dragnet size more standard and accurate. The varieties of weldable grids are diversified. The components related to the zonal grid adjustment are adjustable. The meridional grid adjustment is controlled by microcomputer, and different grids can be set. The welding adopts a new closed water-cooled welding network transformer, with a wide range of voltage regulation. In order to adapt to the capacity of the user's main power transformer and reduce the current impact, the welding power electronic control adopts the method of one-time welding and separate control power transmission, that is, when welding the same row of weft wires, the welding transformers work separately. The welding power electronic control system adopts synchronous control technology. The welding time and sub control welding are composed of digital integrated circuits, with high control accuracy and stable performance. The motor power provides flexible welding pressure for the intersection of vertical and horizontal lines. Compared with other welding equipment powered by compressed air, the welding is stable, with less spatter, higher welding speed, lower initial investment, operation and maintenance costs, and lower noise in the plant.

Technical parameters of tunnel mesh welding machine:

Welding width 1.5m

Welding length 2m

Diameter of welded rebar 6-8mm

Number of welded copper heads: 8

The horizontal wire feeding is straightened in advance, and the material is broken automatically

Longitudinal wire feeding, pre straightening and cutting, manual threading

Wire drawing form Step motor wire drawing

Welding principle Current welding

Main motor 3KW variable frequency electromagnetic brake motor

Reducer No. 4 cycloidal pinwheel reducer

Welding speed 40-55 rows/min

Voltage 380V 50HZ

Head size 2m x 1.6m x 1.5m